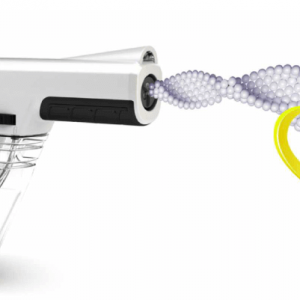

Working principle of electrostatic sprayer

The electrostatic sprayer is mainly composed of two parts: a hand-held ultra-low volume sprayer and a high-voltage electrostatic generator. A high-voltage electrostatic field is formed between the sprayer and the crop. When the medicine liquid passes through the sprayer, high-voltage electrostatic electricity is generated. Under the action of the electrostatic field, the droplet moves in a direction and is sprayed evenly. The droplet can be absorbed evenly on the back of the leaf and the branches.

Disinfection is the method of killing pathogenic microorganisms. The effect of disinfection is usually achieved by chemical means. The chemical used to disinfect is called a disinfectant. Sterilization is a method of killing all microorganisms (including bacterial spores) on an object, usually by physical means

To meet the needs of pest control, a combination of pressure atomization and wind atomization is used. The strong airflow of the fan is used to send the medicated droplets to a distance. Low volume spraying and electrostatic spraying are used to increase the adhesion of the droplets, a kind of high-efficiency electrostatic high-jet long-distance sprayer suitable for agricultural vehicles was successfully developed. The experimental results show that the electrostatic sprayer can reach 45 m in horizontal range and 22 m in vertical range, the working speed of prevention and control is fast and the working productivity is high, and the spraying rate is 3. 24 HM/h, the pure spray rate is 39 hm/H when the spray is horizontal.

The electrostatic sprayer system is mainly composed of a frame, medicine box, liquid pump, fan, low volume sprayer, electrostatic system, and spray control system. The whole machine is powered by a gasoline generator. The electric control system controls the rotation and swing of the air duct, the start-up and stop of the air blower, the start-up of the electrostatic system, and the medicine pump.

The principle of the system is that pressure atomization is combined with wind atomization, and the strong airflow of the fan is used to send the drug-containing droplets to high places and far places, and then low-volume spray and electrostatic spray technology are adopted to increase the adhesion performance of the droplets and reduce the drug loss, to increase the virulence.

Attentions of using electrostatic sprayer

1, do not use wet hands and other dangerous ways to operate charging, avoid electric shock;

2. When charging, first connect the connector of the Charger to the sprayer, and then connect the plug of the charger to the power socket. Make sure that the voltage of the power supply used is 220V, if the voltage fluctuation is large, it is possible to damage the charger;

3, the first three use charge time to 12 hours or so, later use charge time to maintain between 5-7 hours, should not be too long, if the charge time is too long, the battery heating, will reduce the battery active liquid, will reduce the capacity of the battery, affect the battery life;

Test and spray test

1, check the connection parts whether there is leakage phenomenon if there is running, leaking, dripping, leakage phenomenon, please connect correction or replace the gasket, to prevent the liquid medicine harm to the body or the crops;

2, check whether the spray is uniform, continuous, if the pump pressure is not stable, there may be intermittent spray or not fine, a water column, at this time may be filter, pipe, nozzle and other impurities blocked, or because the battery is low;

Use of electrostatic sprayers

The electrostatic spray uses high-voltage static electricity to set up an electrostatic field between the nozzle and the spray target. When the liquid is atomized by the nozzle, the droplets are charged, and the charged droplets move directionally under the combined action of the electrostatic force and other external forces, it’s attached to all parts of the target. To administer the drug.

It is characterized by: (1) uniform droplet size, good penetration, uniform deposition coverage, especially on the back of the target can be deposited; (2) good adhesion, so that the phenomenon of droplet loss caused by wind and rain is greatly reduced; Environment pollution is small. It’s got a lot of potentials. Its disadvantages are complex structure, high mechanical cost, high safety requirements during operation.

At present. There are three basic methods of charging the droplets in electrostatic sprayers, namely Corona charging, inductive charging, and contact charging. The schematic diagrams of these three charging methods are shown in fig. 7-16. The structure, type, charging effect, and safety of the nozzle should be considered when selecting charging mode. Should make the nozzle with a lower working voltage and current, and require the nozzle structure compact, simple, good insulation.

In general, contact charging can make droplet charging the most full, the best effect, but the high charging voltage requirements, insulation requirements are also very strict. The effect of inductive charging is lower, and the required charging voltage is lower, but it may cause electrode wetting and failure. The corona charging effect is poor, and the electric energy consumption is also big, but the structure is simple, the insulation requirement is lower, the cost is low. In practice, all three charging methods have been used, sometimes the two methods can be combined to apply.

The electrostatic sprayer is different according to the structure type. Can be divided into hand-held, Knapsack, vehicle-mounted, traction and fixed, and so on. The vehicle-mounted type and the traction type have great application prospects in landscaping work.